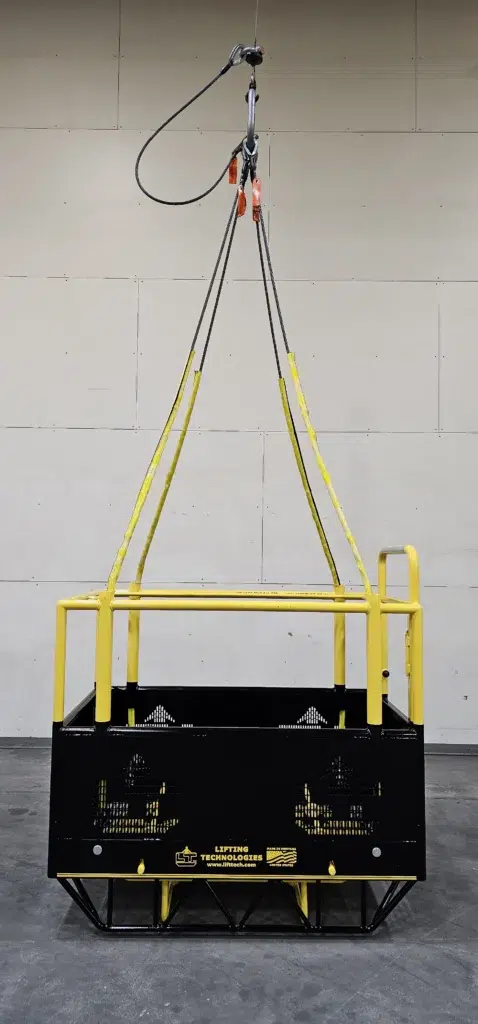

BM2-600G 2-Person Rectangular Crane Man Basket

Premier Series | Two-Person | Rectangular | No Overhead Protection

Product Description

The BM2-600G is a two-occupant crane-suspended personnel platform designed for inspection and maintenance teams that need shared workspace at height. Its 36″ x 60″ rectangular footprint provides extended reach along the work face while remaining narrow enough to maneuver between structural steel, pipe racks, and process equipment.

Built to comply with OSHA 1926.1431 requirements for hoisting personnel, the BM2-600G features all-welded steel construction, 42″ guardrails with 6″ toeboards, an inward-swinging access gate, and multiple tie-off points for personal fall arrest. The 600 lb maximum rated load accommodates two workers plus tools and materials, while the approximately 530 lb basket weight keeps the total suspended load manageable for a broad range of crane configurations.

Like all Lifting Technologies Premier crane man baskets, the BM2-600G is manufactured in Missoula, Montana, and ships with complete documentation, including proof-load test certification, inspection checklists, access to Lifting Technologies online video training, and operator guidelines. Each unit is load tested to 125% of its rated capacity—750 lb test weight—before leaving the facility, providing documented verification for site safety and compliance records.

The BM2-600G is widely used in power generation, petrochemical, and construction markets where two-person elevated access improves productivity and safety compared with sending a single worker or erecting scaffolding. The rectangular platform gives crews the linear reach they need for joint inspections, component replacement, and other team-based tasks along beams, pipes, and structural members.

Industrial Applications

Power Generation & Utilities

Power generation facilities depend on crane-suspended platforms for access to boilers, ducts, precipitators, and turbine hall structures where scaffolding is impractical. The BM2-600G’s 36″ x 60″ deck gives two-person teams room to handle generator exciter inspections, economizer repairs, and air heater work where a technician and helper must share tools and instrumentation along boiler walls or duct sections.

Petrochemical & Refining

Refineries and petrochemical plants use personnel platforms for column tray inspections, exchanger work, and pipe rack maintenance during planned turnarounds and unplanned repairs. The BM2-600G supports two-person tasks such as heat exchanger bundle support work, column tray inspections, and small-bore piping repairs along pipe racks where a rectangular footprint improves reach while keeping the team within an OSHA-compliant platform.

Manufacturing & Industrial

Manufacturing and industrial facilities rely on personnel platforms for overhead crane maintenance, conveyor repairs, HVAC service, and access to ceiling-mounted equipment without disrupting operations. The BM2-600G’s 2-person, 600 lb configuration allows maintenance teams to work together on overhead crane rail maintenance, conveyor drive repairs, and exhaust system service while staging tools and components on the 36″ x 60″ deck.

Features & Benefits

Spacious Two-Person Work Platform: The 36″ x 60″ deck provides sufficient room for two workers, tools, and materials, enabling team-based inspection and maintenance without crowding and reducing the need for separate lifts for companion tasks.

Rectangular Extended-Reach Design: The rectangular footprint offers extended reach along beams, pipe racks, and structural members, reducing the number of crane moves required for linear tasks and improving efficiency on long work faces.

OSHA-Compliant Construction: Designed to meet or exceed OSHA 1926.1431 requirements for crane-suspended personnel platforms, with 42″ guardrails, 6″ toeboards, an inward-swinging gate, and multiple fall protection anchor points to support 100% tie-off.

Proof Load Tested to 125%: Each BM2-600G is proof-load tested at 750 lb (125% of its 600 lb rated capacity) before shipment, and ships with test certificates, inspection records, and serial-number traceability to support site safety documentation.

Optimized Weight-to-Capacity Ratio: With a basket weight around 530 lb and a 600 lb rated capacity, the BM2-600G balances robust construction with manageable total suspended load, making it compatible with a wide range of cranes and rigging setups.

Frequently Asked Questions

What OSHA regulations apply to the BM2-600G?

OSHA 1926.1431 governs the use of crane-suspended personnel platforms in construction. This standard covers proof-load testing, guardrail and toeboard geometry, fall protection anchor points, and documentation requirements. The BM2-600G is engineered and manufactured to comply with these regulations, and Lifting Technologies provides supporting documentation to assist with site safety and compliance programs.

How much weight can the BM2-600G hold?

The BM2-600G has a maximum rated load of 600 lb, including both occupants, plus tools, materials, and personal protective equipment. For example, two workers in full PPE may use most of this capacity, so remaining allowance should be reserved for shared tools and small components; the basket weight of roughly 530 lb results in a total suspended load of about 1,130 lb, excluding rigging, and each unit is proof-load tested at 750 lb prior to shipment.

How many people can work in the BM2-600G?

The BM2-600G is rated for two occupants. The 600 lb capacity is intended to cover both workers plus their tools and PPE, so lift planning should allocate capacity per person and ensure that combined worker and tool weight remains within the rated load.

When should a two-person rectangular basket be used instead of a single-person model?

Two-person rectangular baskets like the BM2-600G are ideal when tasks require a technician and a helper, such as lifting and positioning components, conducting two-person inspections, or performing work that benefits from an extra set of hands along a linear work face. Single-person models are better suited to solo inspections in extremely tight spaces where maximum maneuverability outweighs the benefits of shared workspace.

Can the BM2-600G be customized?

Yes. Lifting Technologies can customize the BM2-600G with options such as extended height guardrails, additional tool or material trays, specialized rigging configurations, additional fall protection anchor points, and custom paint colors for site or corporate identification. These modifications can be tailored to project requirements and regulatory expectations.

What documentation is supplied with the BM2-600G?

Each BM2-600G ships with proof load test certificates, operator guidelines, pre-use inspection checklists, access to Lifting Technologies online video training, and product specifications. Additional documentation can be provided on request to support regulatory compliance, customer safety programs, and equipment onboarding processes.

Find Out More

For single-person rectangular access with lower capacity, see the BM1-300G. For larger rectangular crew platforms, see the BM3-900G and BM4-1200G models in the same Premier series. For an overview of options and regulatory guidance, visit the Premier Crane Man Basket page and the Crane Man Basket OSHA Regulations page.